I signed up for a workshop weaving with “Magic yarns” taken by Rene Corder-Evans. I had to take a loom with me, so took my old 4-shaft table loom.

I wound a 5m warp with 201 ends (198 + floats) of black 16/2 mercerised cotton with 4 ends in hand (50 turns of the warping mill + a single end). I spread the ends 8, 8 ,12 ends per slot in the raddle as I wanted ~22cm on loom width. I threaded up the heddles using 9 repeats of a point twill

1 2 3 4 1 2 3 4 1 2 3 4 3 2 1 4 3 2 1 4 3 2 1 with a float at each end. The warp was sett at 23epi (10 dpi reed sleyed 2, 2, 3 ends per dent). The warp was tied to the front apron rod, a header woven to spread the warp. I then hemstitched on 2 picks plainweave and wove 1cm of point twill diamonds to check threading.

Shaft lift plan: plainweave 1,3 + 2,4; 2/2 twill 1,2 + 2,3 + 3,4 + 4,1; 3/1 twill 1, 2, 3, 4

I was then ready to go to the workshop!

At the workshop there was a selection of active yarns and metal yarns to try. I left a gap in the warp between weft sections. I wove various patterns (plain weave, 2/2 twill & 3/1 twill) with sections of 16/2 cotton using:

Silk/Camel

B Chizimi (shrinking yarn)

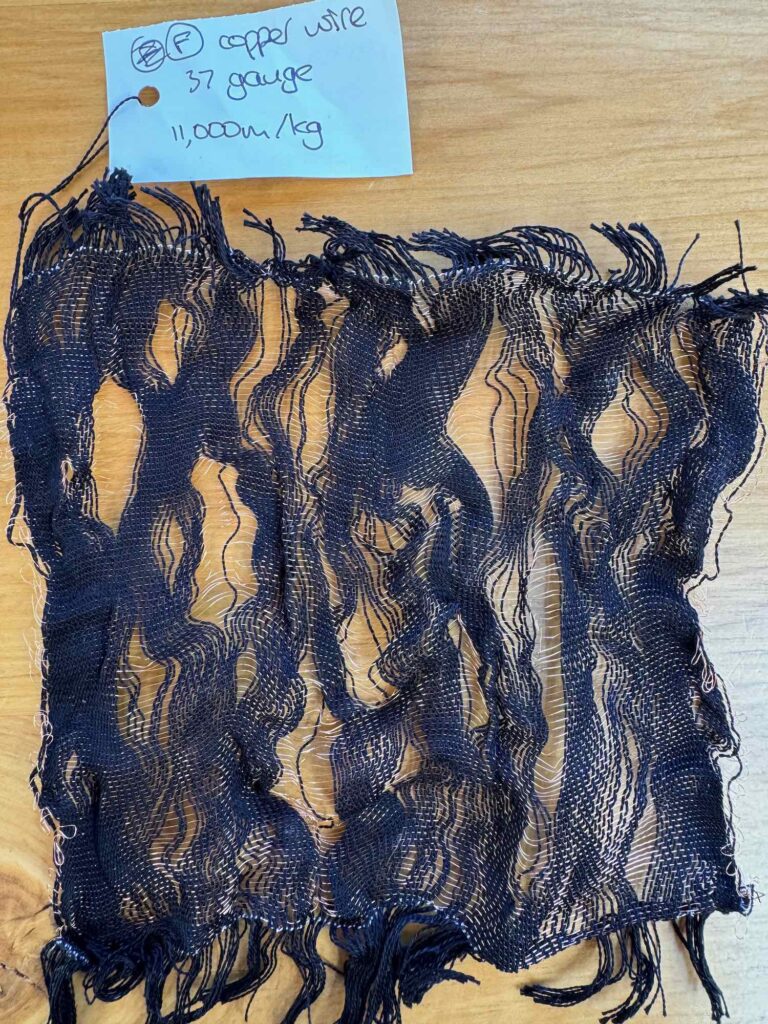

F Copper wire – one piece with pattern sections and a second piece with loose plainweave

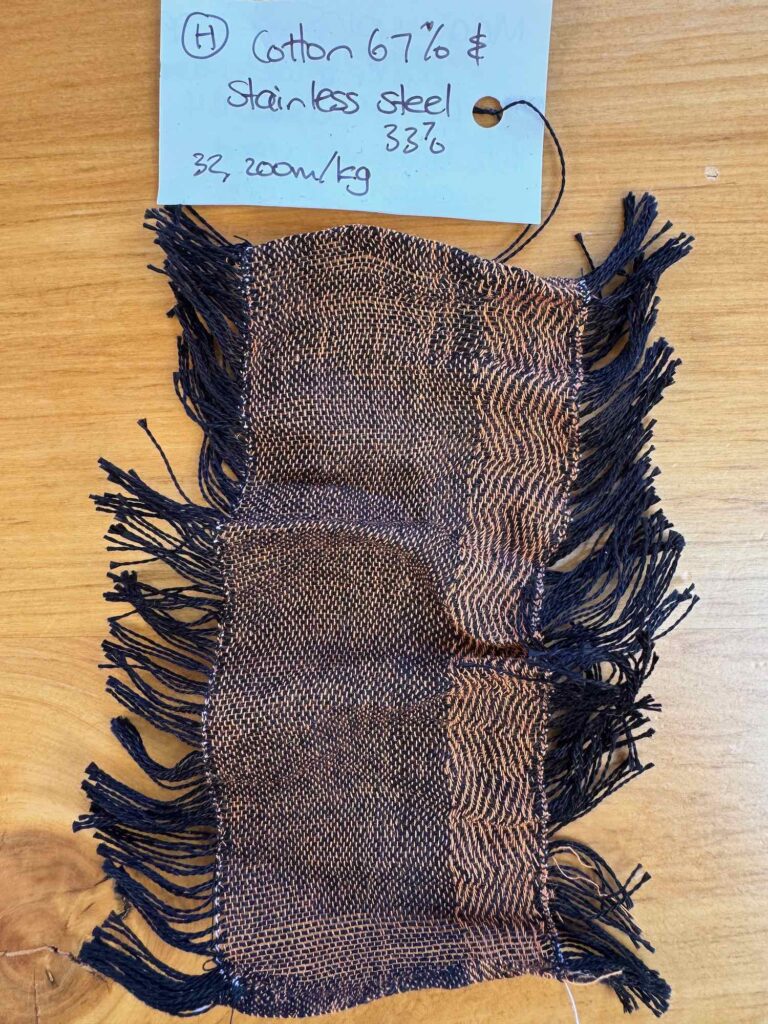

H Cotton/Stainless steel

I Cotton/Lycra

J Elastic

K Silk/Lycra

L Colcolastic

N Linen paper

R Overtwist wool – firm beat and then softer beat

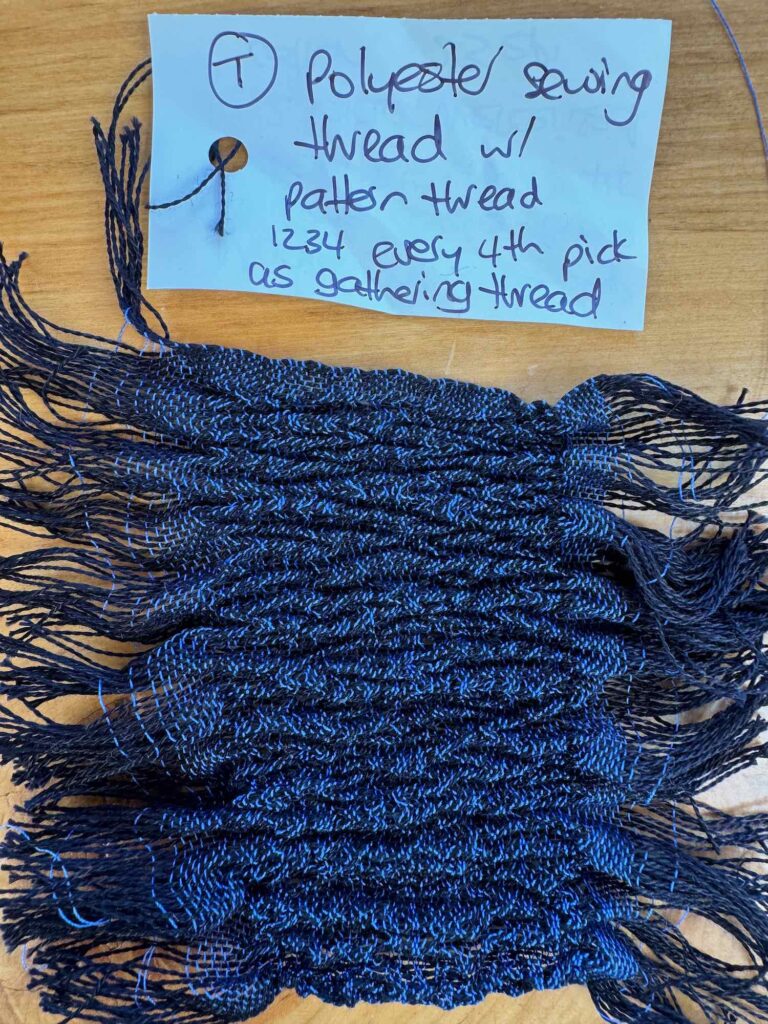

T Polyester sewing thread in plainweave with a 3/1 point twill pattern pick in 16/2 cotton every 5th pick.

Once home, I removed the fabric from the loom and machine stitched the ends of the non-active yarn samples – silk/camel, wire yarns and anywhere that the 16/2 cotton was at the ends.

Non-active yarns were wet finished and laid flat to dry.

Active yarns were heat-treated to activate the elasticity.

Chizimi was steamed with an iron – the iron was held just above the fabric.

Polyester sewing thread – The cotton picks were used as a gathering thread to scrunch up the piece once it was off the loom and the fabric was boiled for a couple of minutes to set the polyester in the pleated pattern. Once cooled, the gathering threads were removed. This produced a woven shibori fabric.

All others pieces were dunked in a pot of boiling water.

I also photographed a couple of Rene’s samples – they can be seen at the end of this gallery.

The first shows a woven shibori fabric using silk/lycra yarn every few picks to create gathers after heat-treatment.

The second shows a wool piece with elastic yarn every few warp ends. This gave a fabric that moved like a spring when held vertically.