It’s almost time for our local Christmas market! I decided to use a design from a recent episode of Jane Stafford’s School of Weaving (S09E06, deflected double weave, 4 shaft placemats design 2) to make some placemats that include reeds and sticks.

The first thing to do was to go out into the paddock and cut some reeds and straight sticks so that they can dry before I need to use them in the weft of the placemats. As they dry, they will shrink; it’s best that they shrink before I weave with them to minimise the chance of them slipping out of the warp.

The reeds I cut are Juncus spp. and the sticks are Māhoe (whiteywood, Melicytus ramiflorus)

Warp yarn – Ashford 5/2 mercerised cotton – Denim blue, Radiant orchid, Friar brown

Weft yarn – Ashford 5/2 mercerised cotton – Denim blue, Twilight grey (once I run out of denim blue)

Total ends = 312 (80 denim blue, 120 radiant orchid, 112 friar brown)

Wind warp with a single end in hand (I only have a single, almost empty, cone of each colour)

Warp length – 4m long (each piece will be about 32cm long)

On loom width – 33cm (spread 8,8,8,8,12 in raddle – 2 slots/cm)

EPI – 24

PPI will vary because of the reeds and sticks.

Reed – 12dpi

Sley reed – 2 ends per dent

Threading, tie-up & treadling can be seen below:

The warp was wound as follows:

40 ends denim blue

14 repeats of 8 ends radiant orchid followed by 8 ends friar brown

8 ends radiant orchid

40 ends denim blue

I spread the warp in the raddle (5 ends/slot), wound the warp onto the warp beam, threaded the heddles, sleyed the reed, tied up the treadles and tied the warp to the front apron rod.

Next I wove the header rows to spread the warp evenly across the fabric and checked the threading.

The warp is 32cm wide on the loom. I decided to weave ~33cm for each placemat and leave a 2cm gap between pieces, that is a fringe of ~1cm at the ends of each placemat. I prefer the fringes to weaving a hem and then hemming each placemat.

Next, I took my reeds and sticks and cut many 35cm pieces.

Each piece involved hemstitching with the weft colour (mainly denim blue, when this ran out, I used twilight grey), weaving 4 rows of plain weave, beginning a pattern using the reeds or sticks until I reached ~30cm, weaving 4 rows of plain weave and hemstitching with the weft yarn.

I then left a gap of ~2cm and repeated the process for the next piece.

I wove 9 pieces in total. The treadling patterns were (T = a pick of tabby – always thrown from the side corresponding to the treadle used for the tabby; A, B are as shown in the tie-up/treadling pictured above, these are where I place the reeds or sticks):

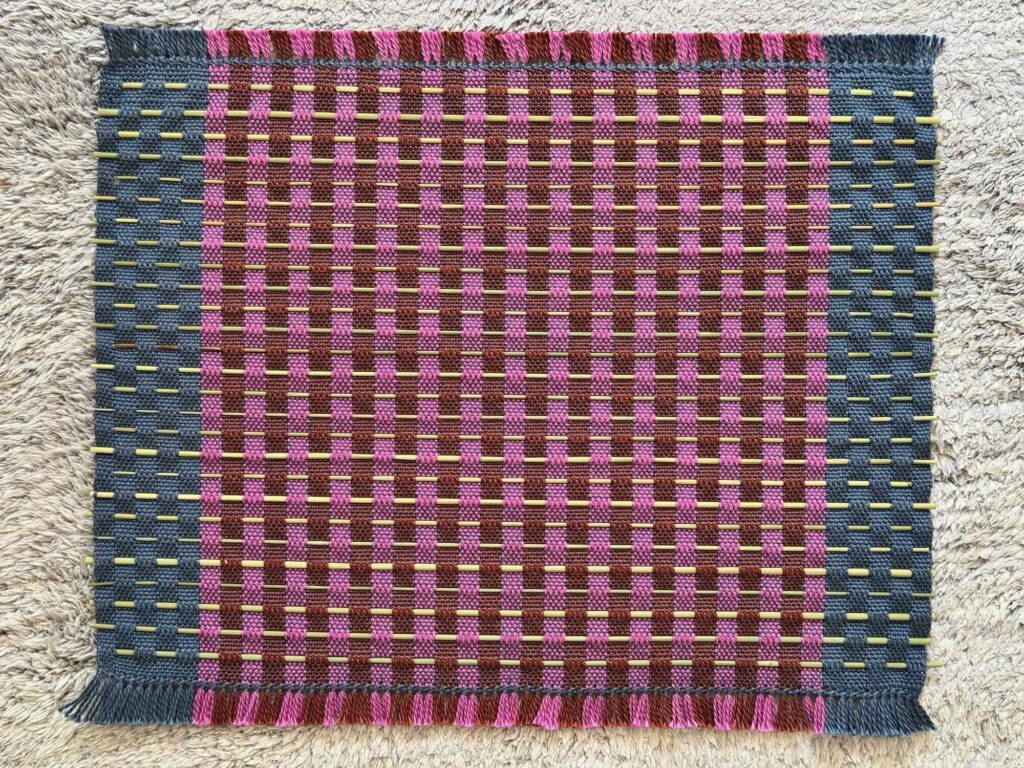

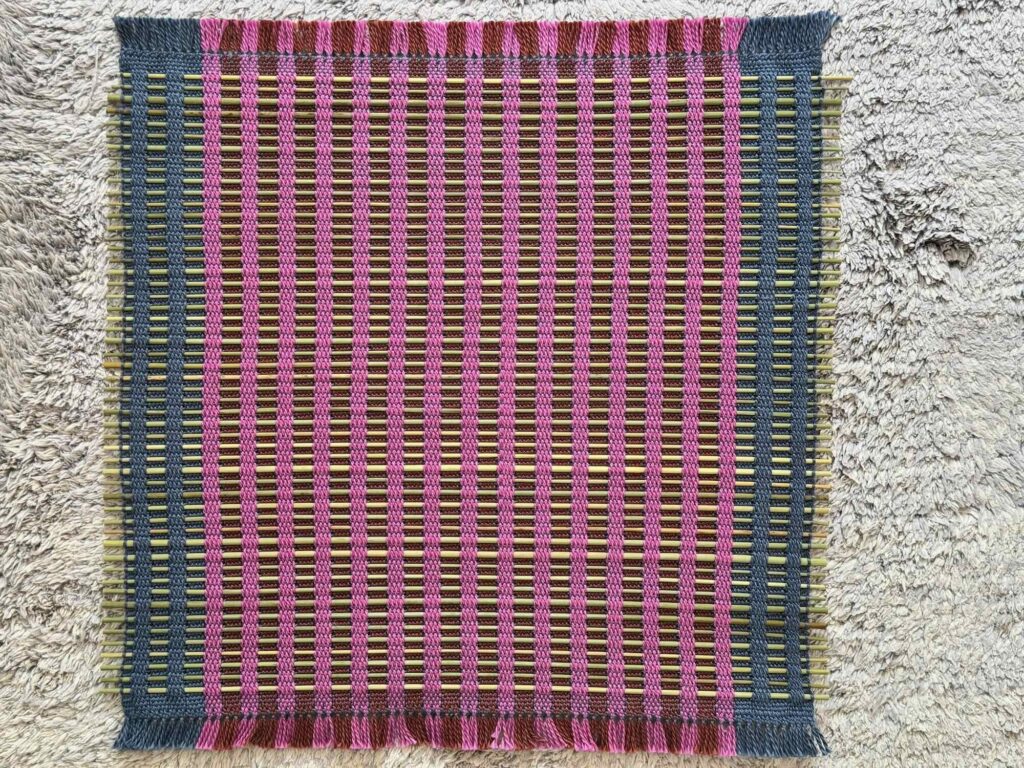

1st piece (reeds) – TTTTTATTTTTB repeated for ~26cm (including plain weave & hemstitching at each end). I stopped early to avoid a couple of knots in the warp.

2nd piece (reeds) – TTTATTTB for ~32.5cm

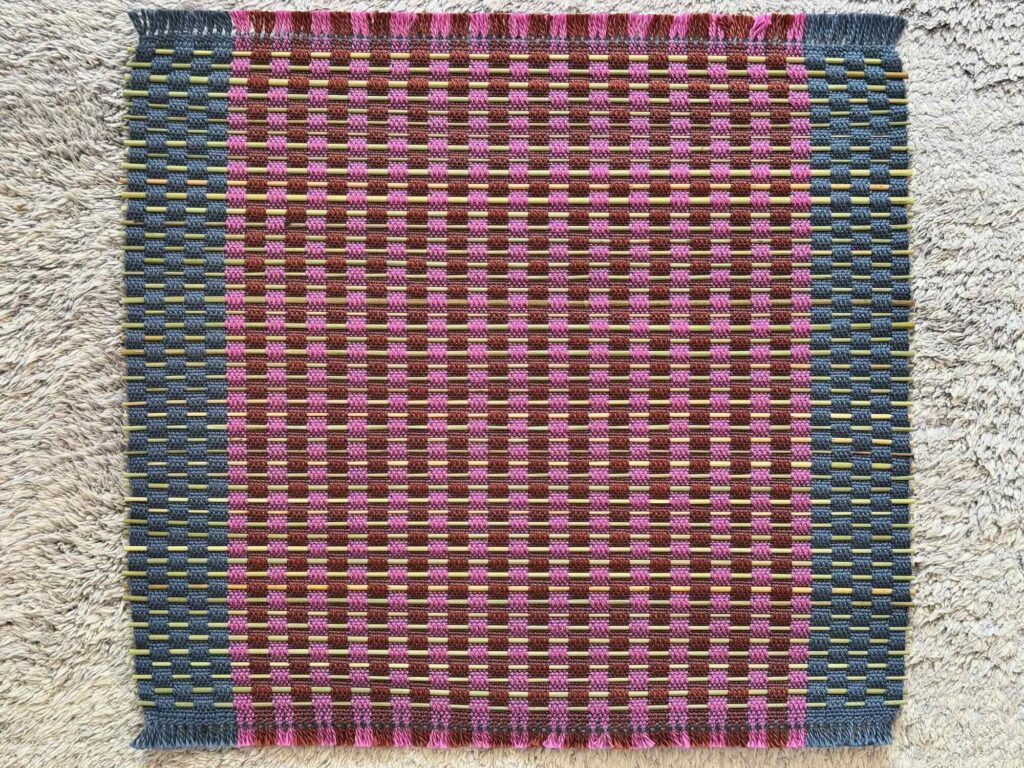

3rd piece (reeds) – TTTTA for ~32.5cm

4th piece (reeds) – TTTTBA for ~33cm

5th piece (reeds) – TTBA for ~32.5cm

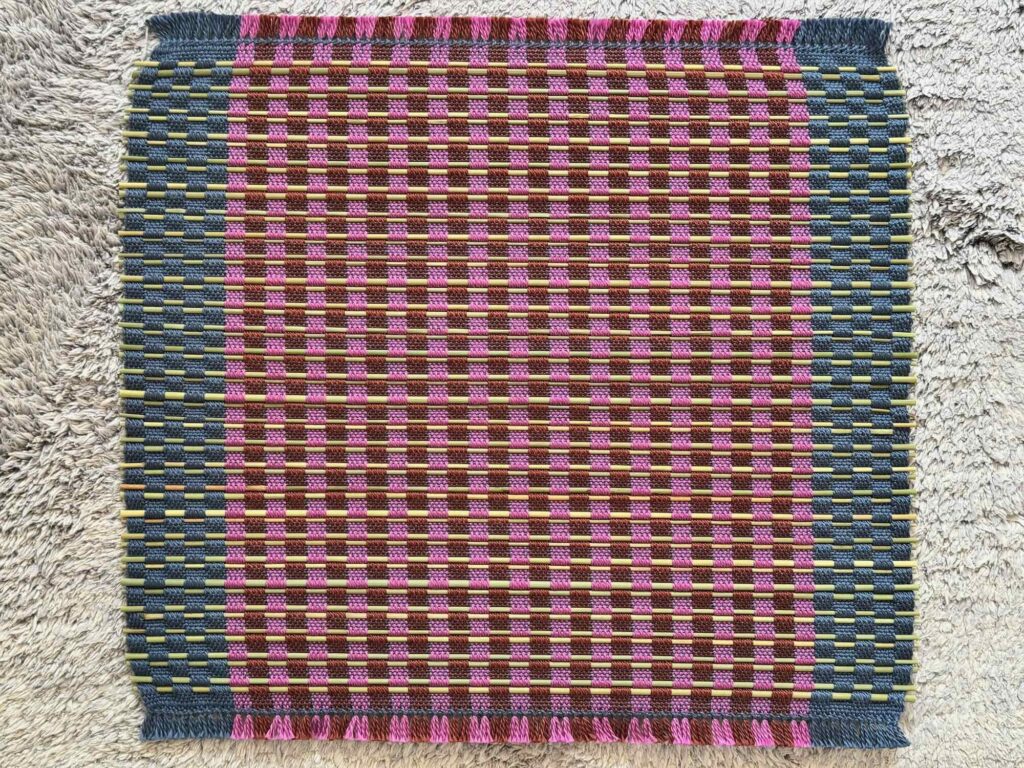

6th piece (reeds) – TTA for ~31.5cm. I stopped a little short because of a knot in the warp. I scalloped the weft up the sides of the reeds for this one.

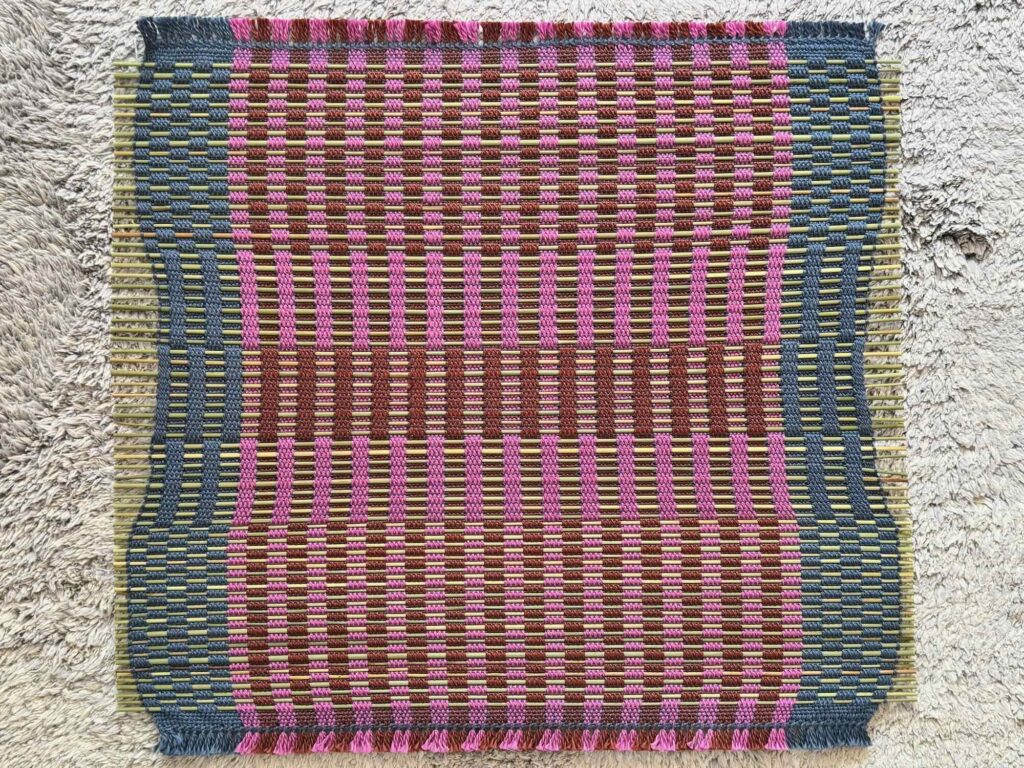

7th piece (reeds) – TBTA for 10cm, TTB 4cm, TTA 4cm, TTB 4cm, TTATTB 9.5cm (was supposed to be TATB! I stopped short as I was out of denim blue weft – I cut a warp end off each side to use for hemstitching)

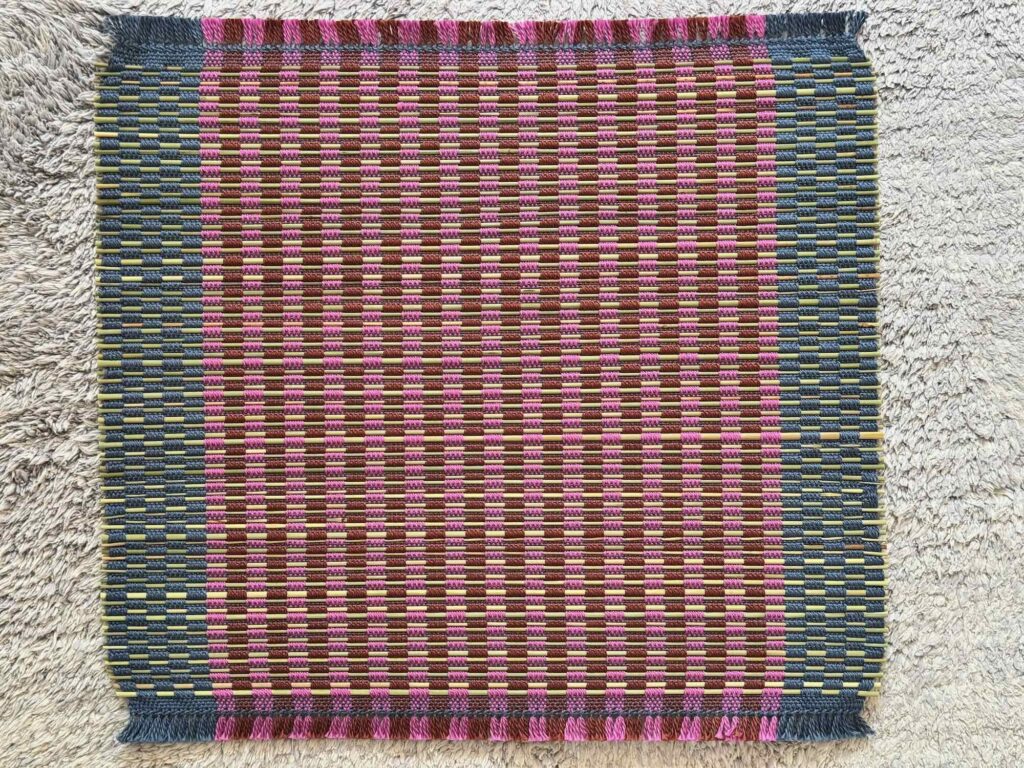

8th piece (sticks) – TTTTA 10cm, TTTTB 10cm, TTTTA 10cm (~7 sticks for each of the three pattern bands)

9th piece (sticks) – TTTTA 7cm (5 sticks), TTTTB (14 sticks), TTTTA 7cm (5 sticks).

There were several knots in the warp where I would be weaving the 8th & 9th pieces. Rather than repair the knots, I wrapped a new length of warp around a T-pin attached to the end of the previous piece, pulled it through the reed and heddles at the appropriate place and hung it off the back of the loom with a weight. The length with a knot was discarded.

Once all of the pieces were completed, the fabric was cut from the loom, the pieces cut apart to leave ~1cm fringes (using a cutting mat, rotary cutter & metal ruler) and loose ends trimmed.

As I couldn’t wash these using the normal wet-finishing process, I sprayed each piece with water and pressed it on a steam cotton setting and then laid them flat to dry. Dimensions of the pieces before and after pressing can be found in the table below, weft size after pressing is not listed as it was the same before and after pressing. All measurements were made at the centre of the warp and weft directions.

Once the pieces were dry, I trimmed the ends of the reeds so that they were flush with the edges of the fabric (pieces 1-5). On piece 6 I left ~0.5cm of reed outside the fabric so that the weft scallops wouldn’t fall off the reed. The fabric of piece 7 has an hourglass shape, so I trimmed the reeds in a straight line ~0.5cm from the widest part of the fabric. I didn’t trim the sticks used in pieces 8 & 9 as they are reasonably even and hard to cut.

| Piece no. | Size before pressing (cm) | Size after pressing (cm) | |

| Warp direction | Weft direction | Warp direction | |

| 1 | 25.5 | 31.5 | 24 |

| 2 | 31 | 32 | 28 |

| 3 | 31.5 | 30 | 28.5 |

| 4 | 30.5 | 33 | 28.5 |

| 5 | 31 | 33 | 28 |

| 6 | 29.5 | 29.5 | 27.5 |

| 7 | 31.5 | 30.5-33 | 29.5 |

| 8 | 28.5 | 29 | 26 |

| 9 | 33 | 30 | 30.5 |