A friend has asked me for an eri silk scarf similar to those from Warps 33 & 37. She particularly likes the indigo warp, natural weft and coloured stripes of hand-reeled mulberry silk from Warp 37.

I sent her some ideas and we have decided that it will be an indigo warp with a predominantly natural weft, mainly eri silk, with some hand-reeled mulberry silk areas. There will be coloured bands – as many of hand-reeled mulberry silk in two shades of green/blue, also copper & gold as yarn allows.

Another friend has also asked for an eri silk scarf from this same warp. She would like only eri silk weft – predominantly natural, with coloured bands of brick/green/brick & green/brick/green.

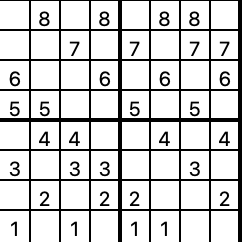

I have decided to try handweaving.net draft #79248 this time. If the initial sample is not good once wet finished, then I will re-thread the warp and weave the same pattern as Warps 33 & 37 (#70110).

I started out by adjusting the pattern threading slightly to get a symmetry that I prefer.

There are 130 ends in each pattern repeat. I will thread 4 repeats and add 3 ends – 1 for symmetry & 2 as floating selvedges.

I began by winding a skein of indigo eri silk into 3 balls (already had some balls from the earlier warps). Next, I wound the 2 skeins of green/blue hand-reeled mulberry silk into balls. The lighter shade took a the longest to wind as the tension of the skein was very uneven. This meant that some skein loops were tight on the swift while others were quite slack. The tight loops trapped the looser loops causing snags and the looser loops would fall off the swift. However, I managed to wind it into a ball eventually.

Once I had the balls, I wound the warp on the warping mill:

523 warp ends – all indigo ends (wound with 4 ends in hand)

Warp length 6.4m (sample, 2 commissioned scarves and an extra scarf)

EPI = 43

Reed = 16dpi, sley 2 3 3 per dent

Width on loom = 31cm

Then it was time to wind the warp onto the loom. While doing this I broke 4 ends that snagged not he lease sticks.

Heddles were threaded (see below for threading order) and the broken warp ends replaced with new 6.4m lengths at the end of warp – these were tensioned with a warp weight.

The reed was sleyed and the warp tied to the front apron rod, the treadles tied-up to the shafts and the header rows woven.

I’m finally ready to begin weaving!!

I noted the approximate time taken for each step of the process so far:

| Planning | 2 hours |

| Ball winding from skeins for warp and weft | 3.5 hours |

| Warp winding | 1.5 hours |

| Warp to loom | 1 hour |

| Threading heddles | 4 hours |

| Sleying reed | 3 hours |

| Tying to front apron rod and weaving header | 0.5 hours |

| TOTAL | 15.5 hours |