While at the Jiyaliren Silk Village near Hotan in Xinjiang Province, China, I bought 1kg (5 skeins) of hand reeled silk yarn.

This yarn was quite “wiry” and “springy” (see image below). In order to be dyed and woven, the sericin needs to be removed.

I looked online and in my notes from the Maiwa natural dyeing and indigo courses to find out how best to remove the sericin. I read that removing all the sericin from wild silk weakens the yarn.

I collated four of the methods I found online and proceeded as follows:

– Dissolve 8g pure soap flakes/1 litre of hot tap water in my medium sized pot (filled with hot water to about 10cm from the top (~12l water) and added 96g Marseille soap flakes)

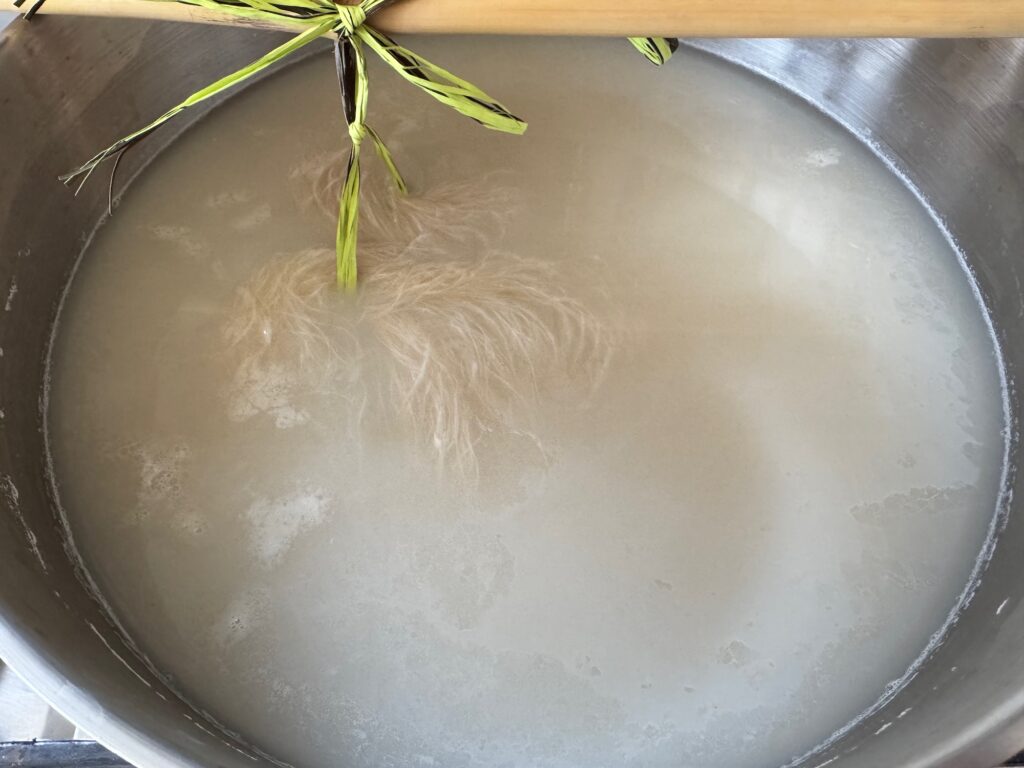

– I doubled a skein over and tied a loose loop of string through the doubled skein. I then inserted a stick through the string loop and balanced the stick across the top of the pot. This meant that the skein was largely kept off the bottom of the pot while being heated. In order to reduce tangling and also to allow good movement of the water in the pot, I treated a single skein per pot.

– Heated to ~80°C; held this temperature for 45-60 minutes; dunked the skein up and down several times over this time.

– Rinsed thoroughly, alternating running tap water rinses with swooshing and soaking in a bowl. I started with hot tap water, gradually cooling to luke warm. I paid close attention to the area of the ties that bind the skein.

– Once the rinse water was mostly clear (5-6 rinses), I soaked the skein for ~15 minutes in 30ml 10% acetic acid in 4l of cool water.

– Next, rinse another 2-3 times in cool water.

– Finally, I rolled the skeins in a clean towel to remove excess water and hung the skeins to dry fully (takes 2-3 days inside on the drying rack with the fan going). Twice a day I rotated the skeins and gave them a fluff.

The yarn is so much whiter, softer and fluffier than before the scouring process. At first, I only scoured one skein to see how the process went. This skein underwent a longer heat treatment than the other 4 skeins (as well as an initial treatment at ~65°C that didn’t do much to the sericin), and accordingly, has more of the sericin removed. I am curious to see if this has weakened the yarn too much for it to be used a warp yarn. It will also be interesting to see how each of the skeins behaves as they are wound into balls! Hopefully, they are not too tangly.

Update 10 October

The last four skeins of yarn were now fully dry. They were a mixture of very soft, fluffy yarn and straw-like yarn – they were no longer wiry. I twisted them into “balls”. After twisting, my hands were left feeling soapy, so I decided to give them another wash in very hot water, rinse well, neutralise and hang to dry again.

I proceeded as follows:

– Fill two medium pots with ~12l hot tap water

– Hang one skein into each pot

– Heat to ~80°C

– Hold temperature close to 80°C for about 30 minutes. The water turned slightly milky and there was some scum on the surface of the water.

– Rinse well by alternating rinsing under running tap water and submerging the skein in a sink of water and “swooshing” it about, particularly at the three ties that bind the skein. The first rinse was in hot tap water, the next in very warm tap water, the next in warm tap water and the last in cool tap water. The rinse water was then quite clear.

– Soak in a bowl with 30ml of 10% acetic acid (white vinegar) in about 4l water for about 15 minutes

– Rinse once again in cool tap water – both a running water rinse and a submerging rinse

– Squeeze excess water out in a towel

– Hang skeins to dry

Update 12 October

The last four skeins of yarn are once again fully dry. They feel a little softer than last time (still a mixture of straw-like & very soft fluffy portions), however, there is now no feeling of soap residue on my hands when I twist the skeins for storage.

| Skein | Before sericin removal | After 1st scouring | After 2nd scouring |

| 1 | 175g | 142g | No 2nd treatment |

| 2 | 216g | 193g | 184g |

| 3 | 216g | 199g | 189g |

| 4 | 218g | 204g | 193g |

| 5 | 228g | 206g | 194g |