Before beginning to weave the headbands, I wanted to halve the width of the warp and tie the extra half onto the warp end to double the length. I did this by unwinding the remaining warp and pulling it through the reed. I had about 2m of full width warp or 4m once doubled. I wanted about 2.5m for headbands and 1m for bookmarks. I found the centre point of the warp and removed the left half of the warp from the warp beam. I rewound the remaining warp onto the warp beam – this leaves the warp slightly off centre – and tied the ends of the warp half that was removed to the ends of the warp remaining on the beam. Once the halves were knotted together, it looked like it would be impossible to wind it onto the warp beam as it was quite snarly, but it all wound through the reed and heddles very smoothly. I had left the original half of the warp with two extra warp ends – one for symmetry and one for a floating selvedge; this meant that I had to cut two new ends to tie on to these.

Once the “new” warp was tied to the front apron rod, I began to weave hairbands. All hairbands were hemstitched at both ends and a small gap left between pieces. I wove six pieces.

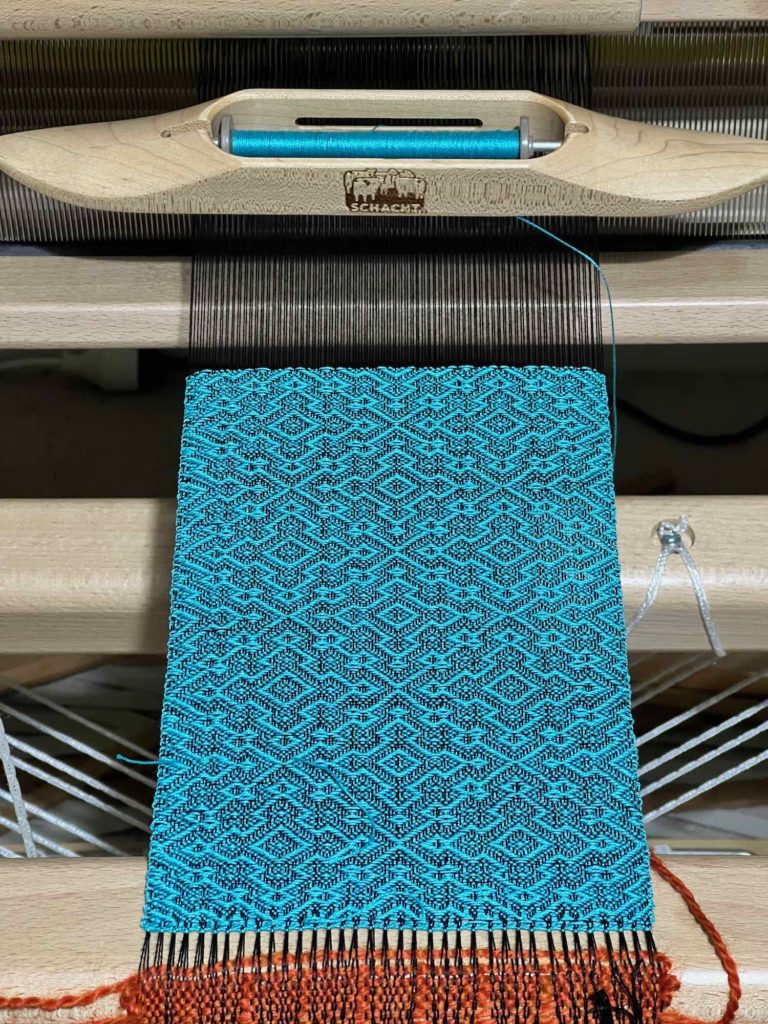

1) TAW treadling with a weft of 10/2 mercerised cotton, colour scuba blue, 7.5 pattern repetitions – I was beating this one too hard as the patterns were not square. This is for a friend.

2) TAW treadling with a weft of No 8 Perle embroidery thread, colour light blue (996); 6.5 pattern repetitions.

3) TAW treadling with a weft of No 8 Perle embroidery thread, colour electric blue (995); 6 pattern repeats.

4 & 5) Point twill treadling (1-8-1) with a weft of rayon embroidery yarn in a rainbow of vibrant colours. The colour sequence can be seen in the image below. This thread is VERY slippery, but it is possible to load the spool of thread into the shuttle, so no need to wind a bobbin. I changed colours by leaving a tail, opening the next shed, inserting the tail and inserting the next colour. This means that there were only 2 ends in a single shed once per colour change and they are different colours, so the double pick isn’t very noticeable. Also, I changed colours on alternating sides; this meant ending one stripe on treadle 2 and the next on treadle 1.

This took me to the knots where the two warp halves were joined.

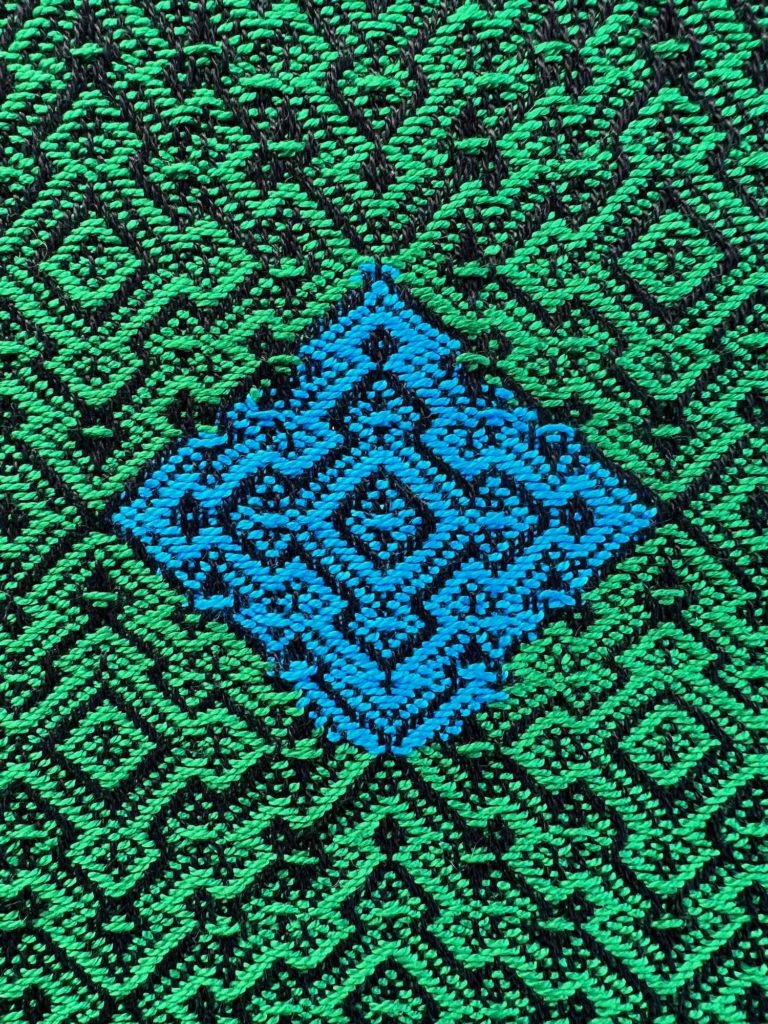

6) TAW treadling with a weft of No 8 Perle embroidery thread, colour dark green (699); 6.5 pattern repetitions. This is for Husband. He requested a discontinuous weft colour inlay (colour 995) in the centre. This was very tricky, but I managed it – albeit with several errors – the overall effect is beautiful!

Once the sixth headband had been woven, I cut all of the fabric from the loom, separated the pieces and washed them in the washing machine on a normal warm water cycle. I then trimmed the loose ends, pressed each piece with a hot iron and hung them to dry.

| Number/Colour | Pre-wash | Post-wash | Black fabric length | Elastic length |

| 1) Scuba blue | 14.5 x 40cm | 14 x 37.5cm | 34cm | 26cm |

| 2) Light blue | 14.5 x 41cm | 14 x 39.5cm | 32cm | 22cm |

| 3) Electric blue | 14.5 x 40.5cm | 14 x 38cm | 33cm | 25cm |

| 4) Rainbow 1 | 14.5 x 35cm | 13 x 33cm | 38cm | 30cm |

| 5) Rainbow 2 | 14.5 x 33cm | 13 x 31.5cm | 40cm | 32cm |

| 6) Dark green | 14.5 x 40.5cm | 14 x 39cm | 32cm | 24cm |

The last step was to sew the woven fabric into a headband. I used a headband I had made previously as a template for lengths (handwoven fabric = 44cm, black fabric = 27cm, elastic = 20cm). The construction involved:

1) Cutting 8cm wide strips of black cotton fabric to the appropriate length

2) Sewing a label to the black fabric just below the centre point

3) Sewing the black fabric into a tube with open ends. Sew with the label to the inside and then turn the tube right-way-in so that the seam is on the inside and the label on the outside

4) Cutting elastic to the appropriate length and inserting it into the tube

5) Sewing the ends of the elastic to the ends of the tubes so that the tube overhangs the elastic by ~0.5cm

6) Folding the handwoven fabric into a 4-fold fan

7) Inserting the ends of the black tubes into an outside fold of the fan and sewing the tube to the handwoven fabric