We visited the Central Sericultural Research & Training Institute in Berhampore, West Bengal, India. At the institute they have carried out extensive research into the growth of silk worms (Bombyx mori) and mulberry trees (the food source of domesticated silkworms), varieties of mulberry trees and improved the domestication of the silkworm.

We were able to view silkworms feeding – you could hear the munching of thousands of caterpillars, see cocoons drying (in order to kill the pupae) and the unreeling of the thread from the cocoon. the pupae are killed before they emerge from the cocoon to enable the unwinding of a single thread from the cocoon. If the pupae are allowed to develop and chew their way from the cocoon, many short threads are produced.

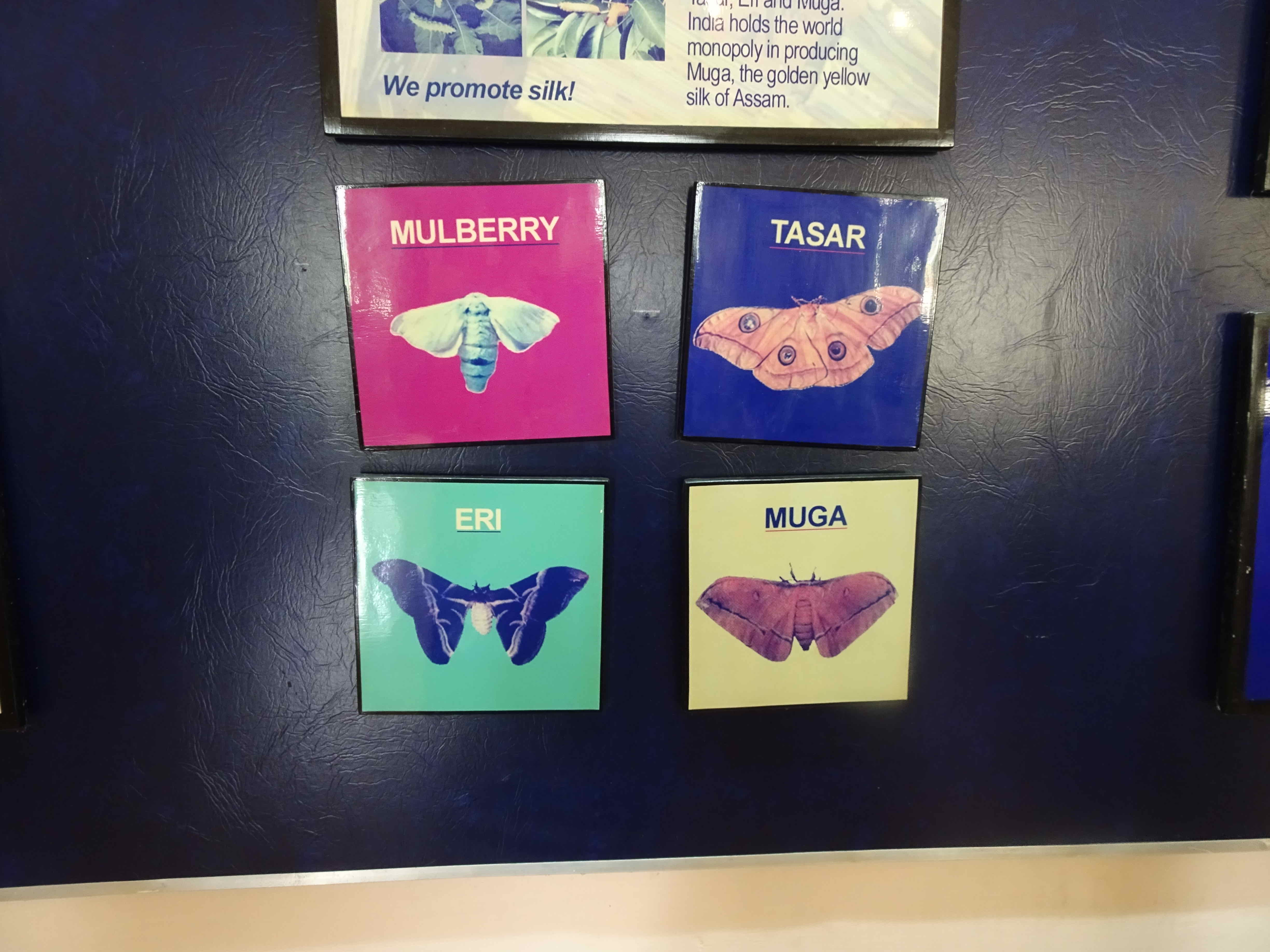

Tussah silk (produced by Antheraea spp.) from India, China and Japan, Muga silk (produced by Antheraea assamensis caterpillars found only in Assam, India) and Eri silk (produced by Samia cynthia) are all produced using cocoons taken from the wild.

Mulberry silk is produced as follows:

- The silk moth lays around 500 eggs

- The silk moth eggs hatch into caterpillars (silkworms)

- The silkworms are fed mulberry leaves

- Once fully mature, the silkworm spins its cocoon over 2-3 days – this involves the production of around 1km of thread!

- The cocoons are baked to kill the silkworm pupae

- The cocoons are soaked in water to dissolve the sericin (the glue that holds the cocoon together)

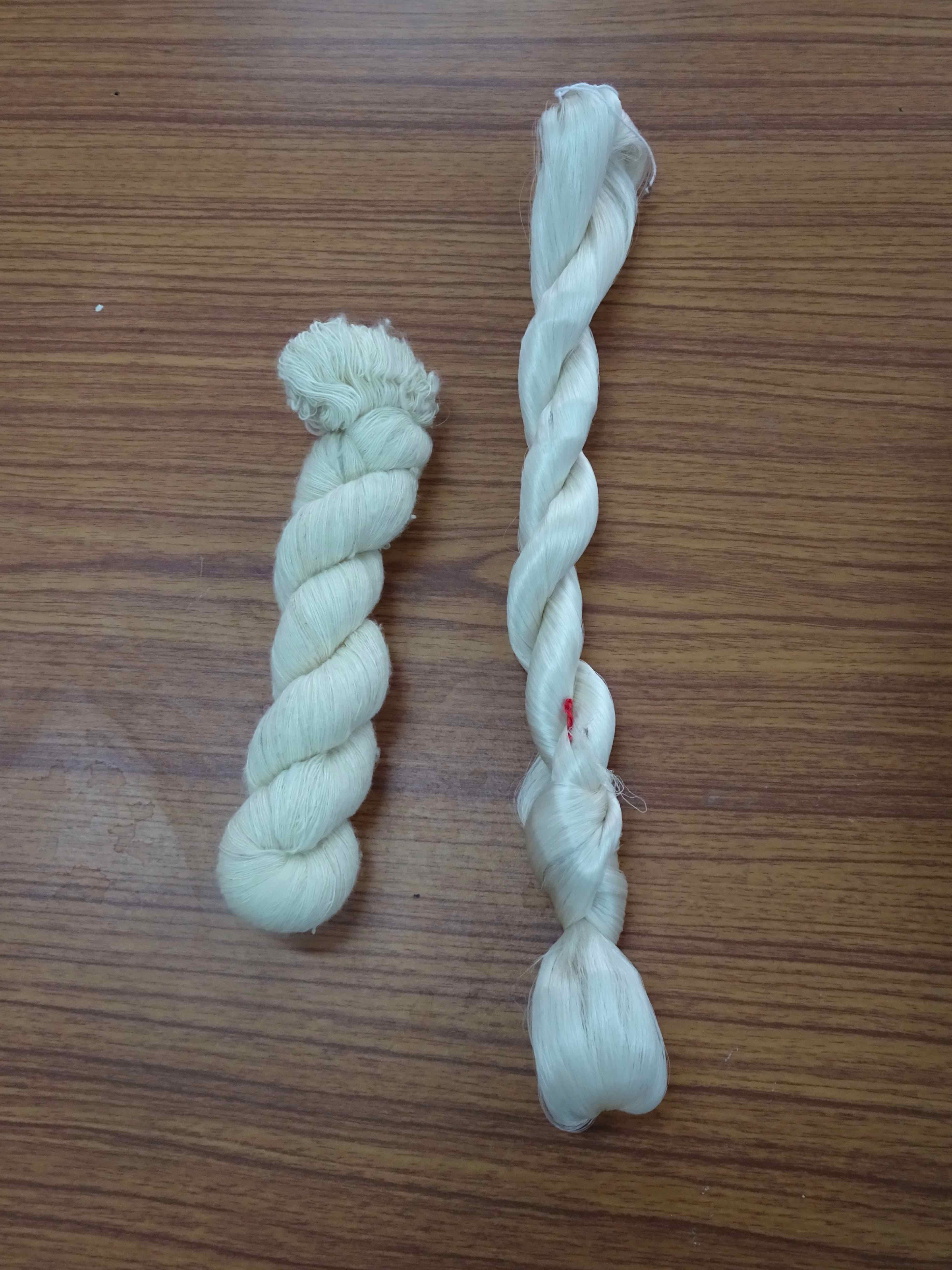

- The silk filaments are then unwound from the cocoon and several strands (from separate cocoons) are twisted together to make a single thread (the spinning process)